Electric car battery article series: Why preconditioning is so important

Preconditioning heats or cools the battery to the optimum temperature range for charging. Goal: shorter charging times, longer service life of the storage tank.

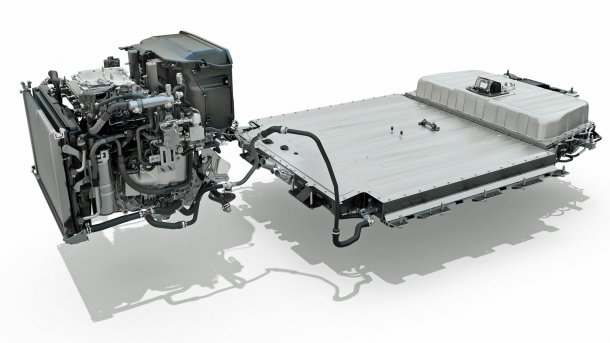

Good battery systems have elaborate cooling and heating circuits. Cheap electric cars regulate the temperature via the software alone; they therefore reduce the charging speed radically in some cases if it is too hot or too cold.

(Bild: Renault)

- Christoph M. Schwarzer

(Hier finden Sie die deutsche Version des Beitrags)

For many decades, the focus in the further development of the powertrain in cars was on the engine. With the switch to battery electric drive, this is shifting, as the battery cell is now the focus of interest. Huge sums are currently being invested globally to achieve progress in this area. Energy density, durability, charging performance and, above all, costs must be optimized if the battery-electric drive is to have a chance anywhere in the world.

In a series of articles, we want to show where we are today and where the development is heading. The European Union has set the political framework: From January 1, 2035, only passenger cars with no direct CO₂ emissions may be newly registered. According to current estimates, this will largely be battery-electric cars. Because the industry cannot simply be switched on and off, there will be a continuous ramp-up in the almost twelve years until the deadline.

Gone fast: No one wants to lose too much time during a forced stop at the charging station. That's undesirable anyway, because the powerful DC pillars on the highways are at capacity at peak times. However, electric cars can only achieve the maximum charging power and thus the highest charging speed if the cells in the traction battery are in the ideal temperature window. Tesla was the model for a method that has since been adopted by many manufacturers: Automatic and targeted preconditioning for DC charging over long distances.

(Bild: Christoph M. Schwarzer)

A good electric car calculates the optimal charging stops for a route that is longer than the range. The navigation system indicates where charging is to take place along the route, what SOC (for State Of Charge) can be expected on arrival, and how far charging is required to arrive safely. Tesla has also demonstrated this. Furthermore, this integration of charging stops into the route guidance should be calculated in such a way that the course of the charging curve is taken into account: Many electric cars can absorb a particularly large amount of power at a low SOC; at a higher charge level, the charging power decreases.

Ideal temperature also increases the durability

Preconditioning means that the traction battery is heated or cooled before it arrives at the DC charging station - to the point. After all, heating up in winter, for example, costs electrical energy, which of course has to be paid for. But the benefits are so great that no one who has tried it will give it up: Especially when it's very cold, charging performance can plummet radically without preconditioning. In addition, it ruins the durability of the cells when charging quickly at low temperatures.

Exactly where the best range is depends on the cell chemistry. Lithium ion cells with a cathode mixture of nickel, manganese and cobalt (NMC) feel comfortable at around 20 to 25 degrees. Lithium iron phosphate (LFP) cells, on the other hand, require more like 40 degrees to function optimally, and they are virtually unable to charge below freezing. Traction batteries with LFP cells, such as those found in the base version of the Tesla Model 3 or the MG4, use the current at the start of charging alone to heat up under such conditions. This makes automatic preconditioning all the more important. In extreme cases in winter, the interior temperature may actually drop with a sliding driving mode. The opposite would be a driving style with changing speed and heavy current foot in summer - then the cooling capacity of the traction battery is required.

(Bild: Christoph M. Schwarzer)

Distribute heat efficiently

Temperature management in the traction batteries of modern electric cars is complex. Active heating and cooling is a basic requirement. Heat scavenging is now also part of this: Waste heat from electric motors or power electronics is used to increase efficiency. A high-quality electric car has several heating and cooling circuits that can be controlled separately.

Nevertheless, automatic preconditioning is not installed in all electric cars. What comes as standard in Tesla, BMW, Mercedes and Porsche is not available at all in Volkswagen Group models based on the MEB (Modular Electrification Toolkit), such as the ID.3, which has just been redesigned. Instead, when the battery temperature drops below one degree, the heating system switches on until at least 1.5 degrees are reached. A rigid and limited regulation. In the compact segment, the differences are great; a Renault Megane E-Tech, for example, has all functions from route guidance with integration of charging stops to preconditioning.

(Bild: Christoph M. Schwarzer)

Optional manual preconditioning at BMW

BMW is now going one step further: In the iX, iX3 and iX1, manual preconditioning is available as an alternative to automatic preconditioning for the new model year. The reason for this is that not everyone wants to use the route guidance or, for example, has a regular charging station to which they like to drive. If desired, preconditioning can be triggered in the central menu. Depending on the interior temperature, the battery starts heating or cooling. A guideline for preconditioning is a quarter of an hour. Manual instead of automatically calculated preconditioning can never be perfect, but it is obvious that a smaller distance from the ideal temperature already means progress. Mercedes does not have the manual option. But those who absolutely want to can switch off the automatic one.

(Bild: BMW)

Manual preconditioning should not be confused with what many manufacturers call winter mode: In Hyundai's electric cars, for example, the internal temperature of the traction battery is kept above five degrees plus when the charging plug is in the charging station or wallbox. If, on the other hand, winter mode is activated, heating is also carried out with electrical energy from the battery while driving.

Minimum for long distance

Hyundai Ioniq 5 and 6 have additionally had automatic preconditioning for some time. This was not the case at the beginning of the Ioniq 5's delivery and led to frustration among many users: With a factory specification of 18 minutes for the charging stroke from ten to 80 percent SOC, the Ioniq 5 is one of the fastest electric cars ever. In cold conditions, however, only part of this potential could be used. A shortcoming that has now been remedied.

It should also not be overlooked that low-priced electric cars have few or none of these features. This lengthens the charging time and shortens the durability. Buyers who rarely or never drive long distances will hardly miss automatic preconditioning. For all others, it is the minimum in combination with route guidance including calculation of charging stops.

(mfz)